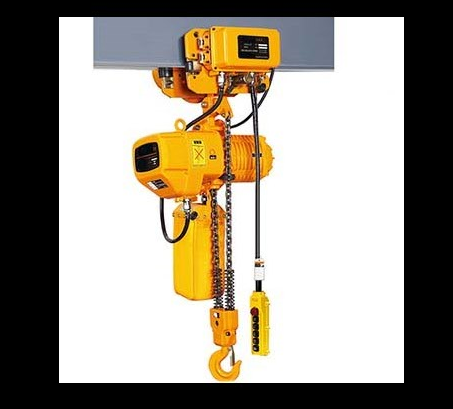

For enterprises looking for equipment to lift heavy loads, there is no better choice of equipment than the electric hoist and in particular, the 2 tons hoist. The 2 tons rates hoist is designed to meet the average needs of most factories, making it very popular.

Furthermore, what makes the electric hoists popular is the fact that they improve the productivity of enterprises, owing to their efficient design. They also reduce the cost of operations, especially the costs related to internal logistics. Electric hoists also improve the working environment within the factory since it is quite quiet compared to alternative load lifting solutions.

However, all these advantages can only be accrued if the electric hoist in question is maintained well. Having a preventive maintenance program in place ensure that your crane is in prime condition to perform its task smoothly and ever-efficient. Additionally, such a program reduces the risk of shutting down the crane due to breakdowns, thereby negating possible loss that may arise.

Herein, we look at some of the best practices when it comes to maintaining electric 2 tons hoists.

Maintaining Cranes

Cleaning ?cleaning should be an ongoing maintenance job. Cleaning the crane components ensures that the crane does not have a buildup of dirt that may affect its functionality. Of particular interest, while cleaning the crane, is to ensure that crane chain or crane rope is clean. After performing the cleaning task, you should dry every detachable component and store it in a dry environment to avoid rusting.

Inspecting The Crane ?This is another element of maintenance that should be continuously conducted. It is advisable to keep track of the crane components installed and in particular, keep track of the life span of each component. For instance, you should keep track of the hook, the wire rope or chain, the trolley, the brakes, all the lubrication requirements, and hoist gear and take note of their performance as well as life span.

Parts Replacement – At the end of the lifespan of each component, you should replace the component, thus negating stressing other parts of the cranes. Each component that makes up the crane system has a lifespan limit that should not be exceeded. As part of the maintenance program, you should procure and replace the parts that have reached their best before date. To ensure the longevity of your crane, do not wait until the parts wear out completely to replace them. Doing so increases the damaging effects of using worn out parts on other parts of the system.

If any of the above maintenance tasks proves too complicated to handle in-house, it is advisable to contract a crane maintenance company to handle it for you.

Beyond having a proper maintenance program in place, you should ensure that the usage of the crane is done in the right manner and efficiently. Proper usage of the crane goes a long way in ensuring that crane is safe and efficient to use in between maintenance programs. For instance, you should not exceed the recommended load of 2 tons. Additionally, ensure that users lift the load vertically and offer the ground before moving the load horizontally in the warehouse. Want a two tons hoist? Get on https://ellsenhoist.com/2-tons-electric-hoist/.