If you are looking to purchase an pulp molding machine, you are going to want to make sure that you do a thorough research in order to find a reputable manufacturer and machine. The key to finding a good manufacturer for this kind of machine is going to come down to several factors. In this article, we will be going over some of the top things to look for when you are trying to do so.

Factors To Consider When Buying An Egg Tray Pulp Molding Machine:

1. Choosing A Reliable Partner/Manufacturer.

The first step in the process comes down to choosing the right manufacturer for the machine. You want to find a manufacturer that has been producing these kinds of machines for a long time. That way, you know that you are going to be able to find one that is going to provide you with quality service and a quality product. If you are really looking for the best value for your money, it is very likely that you are going to want to go with a partner/manufacturer that has consistently shown their ability to produce excellent egg tray machine for sale.

2. Selecting The Right Machine.

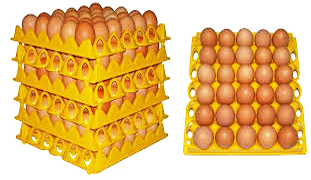

Another thing that you are going to want to do is be sure that you actually select the right egg tray machine for your specific needs. Figure out what you are going to be using the machine for and you should be able to effectively select the right machine for your needs. This will ensure that you find a machine that is going to get the job done.

3. Be Sure To Look At Present and Future Demand.

Another important thing that you will want to do when you are looking to purchase a machine is really try to figure out your present and future demands. It is important to at least consider your future demands because it is going to end up saving you a lot of money in the long run. Not to mention, if you purchase a machine that you are going to be able to grow with, you might even be able to make more money as a direct result.

Another important thing that you will want to do when you are looking to purchase a machine is really try to figure out your present and future demands. It is important to at least consider your future demands because it is going to end up saving you a lot of money in the long run. Not to mention, if you purchase a machine that you are going to be able to grow with, you might even be able to make more money as a direct result.

4. Look At Manufacturers Reputation.

Another thing that you are going to want to do is pay attention to and look at the manufacturer’s reputation on the Internet. You should be able to find ample amounts of information that you can effectively utilize in order to make a well informed decision regarding which one to choose. You want to find and choose a manufacturer that is going to be able to provide you with an excellent machine and excellent after market support. Meanwhile, you should consider the egg tray machine price. Our factory can give you the reasonable price.

As you can see, there is plenty of different factors that you are going to want to look at and consider when you are thinking about investing in an egg tray pulp molding machine. Be sure to really look at the above factors in order to find the best possible partner/manufacturer for your needs.

Helps Fulfil Dream Of Driving

Helps Fulfil Dream Of Driving